Jumpers to set the Micro-Stepping for the stepper drivers.Uses removable A4988 or DRV8825 compatible stepper drivers.2 x End stops for each axis (6 in total).4-Axis support (X, Y, Z, A-Can duplicate X,Y,Z or do a full 4th axis with custom firmware using pins D12 and D13).(Open source firmware that runs on an UNO for Arduino that turns G-code commands into stepper signals) Latest CNC Shield Version 3.0 for Arduino.

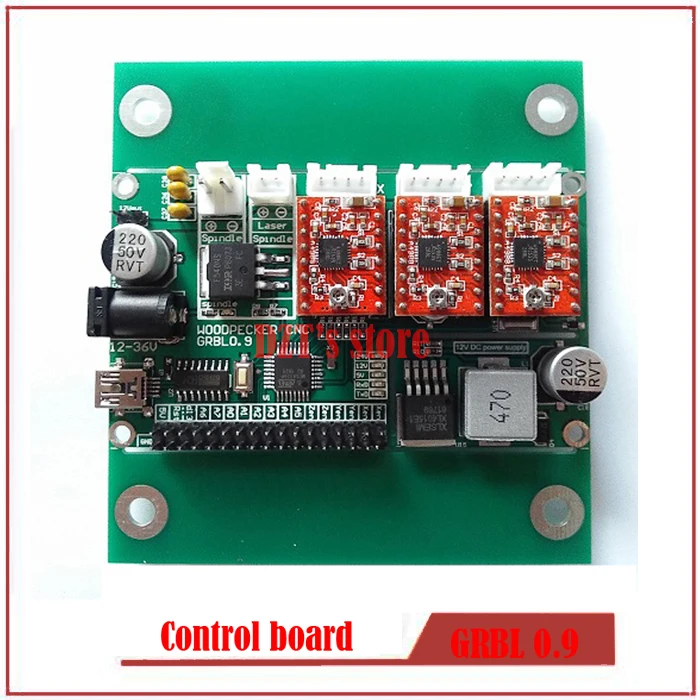

Not all drivers are suitable to run all motors, so when designing a motion control system the driver selection process is critical. There are numerous types of drivers, with different voltage and current ratings and construction technology. The driver (or amplifier) converts the indexer command signals into the power necessary to energize the motor windings.In addition, the indexer is typically required to perform many other sophisticated command functions. The indexer (or controller) is a microprocessor capable of generating step pulses and direction signals for the driver.The following image shows the major components which are be used, this includes a CNC shield for arduino, driver with heat sink and mechanical limit switch.The main disadvantages in using a stepper motor is the resonance effect often exhibited at low speeds and decreasing torque with increasing speed. Advantages of step motors are low cost, high reliability, high torque at low speeds and a simple, rugged construction that operates in almost any environment. The stepper motor is an electromagnetic device that converts digital pulses into mechanical shaft rotation. LINK I referred to for all the information about stepper motors. The following image shows the color code of the bipolar NEMA 17 stepper which I am using for motion of the bed and the plotting pen.The below image shows the final design of our plotting machine which is built out of 6mm transparent acrylic, contains 2 stepper motors for x y axis and servo motor for minimal z axis movement.Craete a Slide for the Group Page as per specifications.Add a plug-in for saving (.gcode) file in Inkscape.Test the Stepper movement through manual control in the Universal G-code sender software connected to the GRBL firmware.Test, verify and upload the example skecth for GRBL.Download and steps to copy the GRBL Library for Arduino IDE.Know more about the CNC Shield with Heat Sink and their connection layout.Getting Started my role and responsibilities

0 kommentar(er)

0 kommentar(er)